Supply Chain Risk Is Inevitable. The Key Is Understanding and Mitigating It via AI.

Supply Chain Disruption

In a series of blog articles, the Product/Solution Marketing team explores innovative solutions to guard against supply chain disruptions.

Our personal and professional lives are filled with risk. Every day, we can take actions that mitigate that risk — or we can throw caution to the wind and hope for the best. Probably the best example is the daily weather forecast. If there’s a 30% chance of rain, do you grab the umbrella, knowing that you’re going to be stuck carrying it around all day, maybe for no reason? Or do you head out the door empty-handed, hoping you won’t get caught in the rain?

Of course, getting wet is a relatively small risk, and a temporary inconvenience. When you’re talking about assessing risk and making the best choices for a global, end-to-end supply chain that spans thousands of miles and involves dozens of trading partners, the stakes are a lot higher. And the threat of “rain” is a complex one, ranging from port closures and materials shortages to tariffs, natural disasters, and blocked shipping lanes. You can’t simply look up at the sky, assessing the cloud cover. The majority of supply chain risk is invisible to the human eye until it suddenly upends both customer promises and corporate financial objectives.

Today’s headlines are filled with examples of this invisible risk. While demand volatility was a primary risk factor over the past two years, today supply-side uncertainty is a fast-growing concern, causing supply chain disruptions and resulting in product shortages for some companies and excess inventory for others.

Supply-side risk and disruptions are taking many forms. China’s “zero COVID” policy and the ensuing lockdowns are making the country’s annual export volumes of over $1 billion extremely unstable and erratic, creating enormous uncertainty for downstream partners. And the country’s recent heatwave caused factories to shutdown potentially resulting in more impacts on the supply chain than COVID-19 lockdowns. In addition, steadily rising raw materials costs are a significant concern for 85.7% of companies that participated in a recent survey by the National Association of Manufacturers. A 150% increase in the price of steel, along with sharply rising prices for other materials, is severely impacting the global construction industry. According to economists, these and other supply-side issues are expected to continue for at least another year.

How much are these risks affecting the typical multinational supply chain? A recent survey of 100 freight transportation, supply chain and logistics professionals, conducted by Logistics Management, found that 82% of organizations are facing greater supply chain challenges today than they did at the height of the COVID-19 pandemic and a 2022 Blue Yonder Supply Chain & Logistics Executives Survey found that 88% of businesses faced disruption over the last year with over a quarter facing significant disruption.

Forget the Umbrella. You Need Advanced AI.

Given the breadth and complexity of the modern supply chain, human cognition and analysis aren’t enough to manage and mitigate risk. While more and more companies are leveraging artificial intelligence (AI) and data science to create dynamic, near real-time forecasts to master extreme demand volatility, they’re also recognizing that these same capabilities can help sense supply-side issues at the earliest opportunity.

Companies can now leverage AI-enabled algorithms, advanced data science and predictive analytics to pull in enormous volumes of structured and unstructured insights from across the end-to-end supply chain — across multiple tiers of suppliers — in near real time. They can use this information to identify risks and vulnerabilities, monitor conditions and proactively make decisions that minimize potential negative impacts, all before the actual “rain” falls.

For example, companies can anticipate an upcoming labor strike, materials shortage, port closure, or COVID-19-related shutdown in advance, instead of scrambling to react after the event has happened. By running a range of digital scenarios in advance, they can strategically choose the best course of action to avoid problems such as stockouts and missed deliveries. They can take action, always, with a full understanding of the impact on cost-to-serve — instead of sacrificing profit margins to maintain service levels, as many companies did during the early months of the pandemic, as they were forced to make quick decisions that weren’t backed by careful analysis.

By identifying and monitoring actual, near real-time risks, companies can profitably adjust production plans, purchase orders, sourcing strategies, inventory movements, and shipments — delighting shareholders and gaining a significant edge over competitors who lack AI-enabled visibility and analysis capabilities.

Not only does the application of advanced AI support better and more profitable supply-side decisions, but it also makes the most of scarce human talent, which is critical given today’s labor shortages across the supply chain. Human analysts can intervene only when needed, relying on AI and autonomous decision-making to manage risk on a day-to-day basis.

Luminate Risk Manager: Purpose-Built to Mitigate Supply-Side Uncertainty

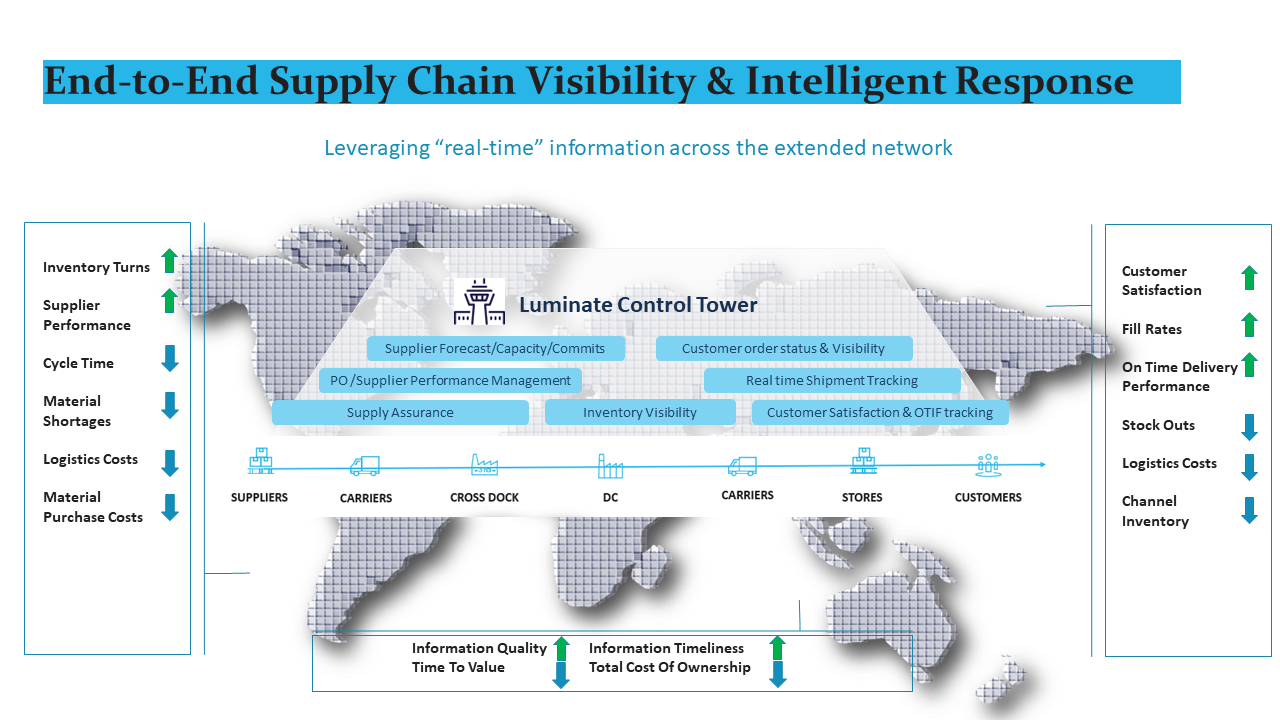

Backed by decades of supply chain expertise, Blue Yonder has developed a new capability in Luminate Control Tower that’s built specifically to help customers recognize, understand and mitigate their supply-side risks. Luminate Risk Manager is a cloud-delivered capability that aggregates global, crowd-sourced data from across the end-to-end supply chain — then intelligently overlays risk scores to identify the biggest sources of uncertainty and vulnerability.

For the first time, organizations can confidently and mathematically assess supply-side risks and prepare the entire network for likely disruptions in advance. They can choose a course of action that fulfills customer expectations while also protecting already-stretched profit margins, whether that means finding alternate materials or suppliers, shifting inventory, adjusting production, or creating new transportation plans.

Weighted scores and multiple risk types enable a quantitative, practical approach to risk management and mitigation — no matter how complex the worldwide supply side is, or how many suppliers are involved.

Luminate Risk Manager is supported by Blue Yonder’s strong partnerships with best-in-class data aggregators, so companies can gain a true, near real-time picture of conditions along the global supply chain, based on internal, external and third-party data. From the everyday risk associated with holding large volumes of inventory to sudden, disruptive events like natural disasters and labor strikes, Luminate Risk Manager supports a new level of supply chain resiliency by sensing, capturing, showing, acting and reporting on real-world vulnerabilities that would otherwise be invisible.

Unfortunately, supply-side risk is a fact of life in 2022. Recent events such as the ongoing shutdowns in China and the Russia-Ukraine conflict have harshly revealed the fragile nature of the world’s supply chains, more than two full years after the onset of the pandemic. Companies that proactively tackle supply-side risk can turn this continued uncertainty into a competitive edge, as they act to ensure product availability, uninterrupted service and profitability before their competitors do — no matter what the daily weather forecast looks like.