Supply chain optimization has never been more essential to overall business success than it is today. A study by Bank of America Global Research, cited by Reuters, found that mentions of “supply chain” increased by 412% in third-quarter earnings calls hosted by Fortune 500 companies this year, compared to 2020.

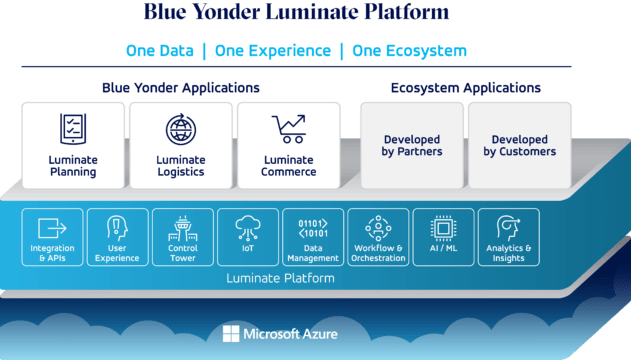

Given the magnitude and increasing frequency of global supply chain disruptions — and the fact that they are projected to last for the foreseeable future ― the capabilities of Luminate Platform have also never been more essential. By creating a connected, boundaryless environment across the supply chain, enabled by artificial intelligence (AI) and machine learning (ML), Luminate Platform helps companies achieve real-time visibility and transparency throughout the end-to-end supply chain network.

The ability to identify exceptions in real time, conduct robust analysis and create an immediate, autonomous response has enabled many Blue Yonder customers to master today’s uncertainty, transforming it into an advantage over less responsive competitors.

It All Begins With a Disruption

You know what they say about the best-laid plans? Today every company has a carefully crafted plan for precisely matching demand with supply, meeting omni-channel customer needs and driving healthy revenues — while also keeping costs down to protect profit margins.

But, even before the chaos of 2020 and 2021, the great majority of supply chain plans proved wrong to some extent.

When a disruption occurs at any point in the supply chain, unfortunately the majority of organizations are simply not prepared. Armed with disparate demand forecasts and planning tools, and separated by traditional functional boundaries, key stakeholders might not even learn of the disruption until it has significantly and negatively impacted overall supply chain performance. At that point, managers likely engage in narrowly focused manual replanning exercises that only consider the outcomes for their own function, instead of the entire supply chain.

These siloed functional responses might be at odds with one another, or with long-term strategic goals, because there’s no visibility, digital connectivity or process orchestration across the larger supply network.

The Power of a Synchronized Response, Fueled by AI

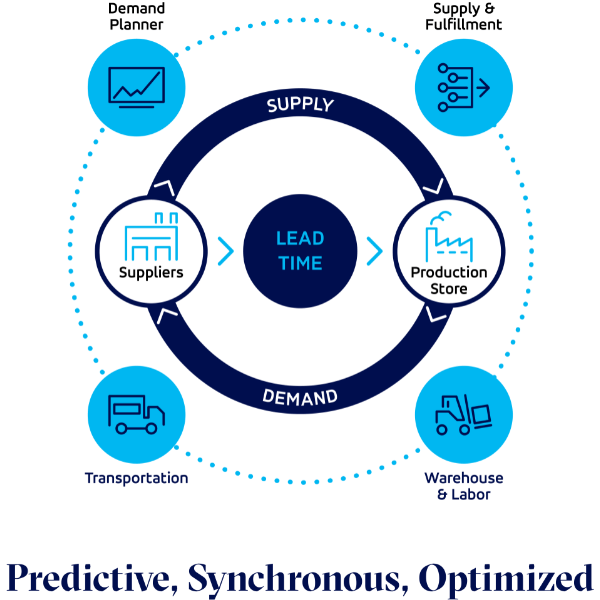

In contrast, Luminate Platform spans functional boundaries and creates an orchestrated, cohesive response across every supply chain competency that reflects what’s best for the organization as a whole.

Let’s consider a disruptive event that every supply chain executive can identify with: a missed delivery of critical products.

Based on meeting pre-defined, network-wide performance targets and honoring real-world constraints, the platform triggers an autonomous response to the missed delivery across the organization’s key competencies.

Supply and fulfillment planning

Once Luminate Control Tower ― which is constantly monitoring the end-to-end supply chain in real time for exceptions — identifies the missed delivery, supply planning engines apply AI to fill supply gaps, including the identification of alternative suppliers and excess inventory across the network. Fed by real-time data, AI-enabled decision engines automatically weigh the cost and service trade-offs of each option. Network modeling solutions ensure the new plan is achievable given the current supply chain structure. The network configuration may be altered, as needed, to manage the temporary supply gap. When the new plan is defined, it’s automatically and instantly communicated downstream to key stakeholders.

Warehouse and labor management

Based on the revised supply and fulfillment plan, warehousing solutions automatically replan the warehouse task list and the labor resources dedicated to receiving the shipment and then fulfilling orders. This work is rescheduled to reflect the new supply plan. To accommodate the sudden change, the intelligent warehouse management system makes decisions to maintain optimal order management workflows, which may leverage alternative strategies like pop-up distribution centers, dark stores and new cross-docking locations. Labor planning also ensures that the appropriate human resources are in place to support ship-from-store, buy online / pickup in store (BOPIS) and other service offerings aimed at delivering personalized omni-channel experiences.

In the transportation function, optimization engines similarly replan labor resources and reassign fleet assets. Equally important, Luminate Platform supports the immediate re-optimization of truck capacities, loading/unloading activities and route plans to maximize efficiency, sustainability and profitability. Enabled by a completely transparent logistics framework, the organization can optimize last-mile logistics in real time as conditions continue to change, using flexible alternatives like external freight networks. At every step, decision engines strategically balance service with cost to ensure the supply disruption will not decimate profit margins.

To complete the closed-loop process, demand planning engines capture the real-time effects of this event and feed them into future forecasts, allowing for a closed-loop process. Store execution measures, such as new category management and pricing plans, are leveraged to reshape demand. The end-to-end supply chain can accurately anticipate the longer-term impacts of this event and reflect them in future plans.

Instead of manual handoffs and disconnected functional replanning, the effects of the supply chain disruption cascade automatically across the network in a synchronous, optimized manner. Planning and execution become one seamless process, linked by a shared view of supply and demand.

Uncertainty Is a Given. Prepare for It with Luminate Platform.

As 2020 and 2021 amply demonstrated, none of us knows what is going to happen tomorrow. The key is leveraging a unified, synchronized platform ― which functions as part of a larger, integrated technology ecosystem — to manage and even master uncertainty. With an API gateway, AI/ML services and an accessible, portal-based interface, Luminate Platform provides the most secure, powerful and intuitive framework to deliver enterprise-scale supply chain responsiveness, in real time.

We’ve seen too many companies struggle to manage the extreme supply chain volatility of the past two years with a set of disconnected technology tools, along with planning and execution processes that are divided across functional boundaries. The result is a disconnected response that often has different functions working at cross-purposes, or placing their own metrics and objectives above what’s best for the supply chain as a holistic, connected entity.

Unfortunately, these unprecedented levels of uncertainty seem to be here to stay. It’s clearly time to leverage advanced technology to achieve the highest level of supply chain synchronization and responsiveness. The world’s leading companies are already embracing the power and control enabled by the boundaryless supply chain. Will your company be next?