Now Moving: Suez Canal, Shipment Visibility and Logjams (Part II)

As traffic slowly resumes in the Suez Canal, rising prices and lost sales are adding ripples to an already strained supply chain. Withstanding this new shock, one that impacted almost $9.5 billion worth of goods daily, means taking another look at resiliency plans in context of this disruption. While we did not expect another crisis that brought the supply chain to a standstill while grappling with the pandemic, we learned that we can still turn crisis into opportunity to help our customers.

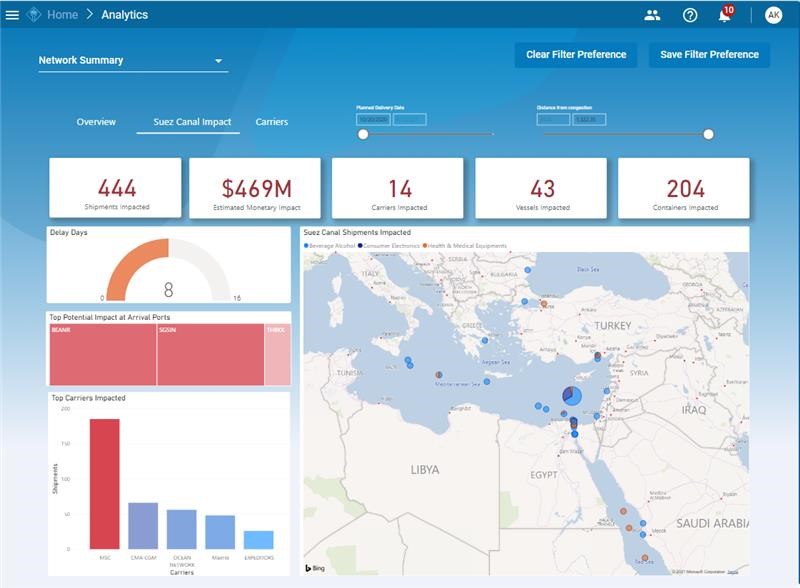

During this crisis, at Blue Yonder we swung into action by forming a cross-functional, internal team across Product, Operations and Customer Success to actively monitor, identify, and track impacted shipments, make rapid product enhancements and keeping customers updated. We have been helping our customers track their vessels and shipments to create action plans for expected delays of 2 to 4 weeks. We are also working with carriers and partners for revised ETAs for impacted shipments so our customers can get a more accurate picture of these delays and the downstream impacts.

So, what can we expect as we recover? As companies begin to mitigate these delays, compounding issues will be an increase in labor needs, congested ports and delayed deliveries. Already running lean operations, factories will struggle to manufacture new goods. Industries operating on low margins, like health care, may also see impacts as the price of goods and services increase due to increased transit time. For consumers, delays will mean trapped shipments and limited access to goods if there are supply chain shortages. Experiences will be reshaped yet again as companies quickly find alternatives to deal with the impacts by expediting and/or rerouting shipments, inventory transfers, etc.

Many companies resorting to air shipments aren’t finding this an easier path as air freight is already capacity constrained. One CPG manufacturer said that in their experience, air freight can take up to 30 days with high costs. They also anticipate a backlog of containers to be unloaded as their warehouses will struggle to cope with delayed arrivals. This will result in running additional shifts to mitigate.

In the mid to long term, companies will be reviewing sourcing strategies as over reliance on longer distance suppliers is leading to higher variability and operating costs. They will look to local suppliers to reduce this reliance even at the cost of potentially procuring more expensive products. Two more lessons gleaned during this crisis that can help alleviate pressure points: visibility and intelligent orchestration.

- Visibility to anticipate demand (and the unexpected). With little room for error, the key to anticipating the unexpected lies in a digitized supply chain that can predict demand and manage inventory projections. Traditional management techniques have to be rethought and injecting real-time visibility should be the first step. Without comprehensive visibility, pain points are left unresolved, informed decisions cannot be made, ultimately resulting in an inability to execute efficiently.

- Intelligent response and orchestration. Consumers last year learned a harsh lesson about supply chain when they could not acquire needed goods. While the full impact of this disruption is still unfolding, businesses can take advantage of what they do know to embed transparency into experiences. Using real-time visibility to form intelligent responses can be extended to customers by keeping them in the loop as shipments are re-routed. Mid- to long-term companies can form remedial plans that look at upstream constraints (single sourcing, regional sourcing) and assess if nearshoring is an option, options of using alternative transportation routes/modes, re-positioning inventory in the supply chain to mitigate such risks, etc.

This is a tricky time for supply chains and Luminate Control Tower can help you prepare for the unforeseen with early visibility so you can create much more informed, intelligent response plans. Check out our free, 30-day trial of Luminate Control Tower to learn how you can build a visible, intelligent supply chain.