Over the past few years, the disruptions of the pandemic and the Suez and Panama canals have highlighted the shortcomings of the traditional ways of running a supply chain. Many businesses are embarking on a digital transformation to turn linear supply chains into connected, intelligent, scalable, customizable, and nimble digital supply networks. Similar in concept to social networks, these supply chain networks are creating breakthrough results and powering business processes quicker and more effectively, while handling the increased variability that the world continues to face.

Digitally transforming the supply chain into a Digital Supply Chain Network allows parties to collaborate on the same shared objects using shared applications.

More importantly, these networks are changing the way business is done by allowing companies to organize, manage and engage, their partners for a competitive advantage. More than just “moving to the cloud”, these networks enable game-changing multi-party or multi-company applications by enabling all-parties to better manage capacity and keep their focus on the end-goal of customer satisfaction.

What’s driving these new supply chain networks?

It started before the pandemic, though the pandemic increased the urgency with which companies are transforming their supply chains. And today, that urgency continues.

Multi-enterprise supply chain business networks support a community of trading partners that need to work and communicate across multiple enterprises with an end-to-end and shared focus. Such solutions provide their community with multi-enterprise functionality, services, and security with special emphasis on supply chain visibility and executional processes.

Gartner analysts Christian Titze and Simon Bailey wrote in a report that “multi-partner digital ecosystems are becoming the pre-eminent form of collaboration to support new digital business models.”

The end of vertical integration and the rise of specialization is creating huge competitive advantages to those companies that can leverage their partners most effectively. Networks are particularly important for companies that deal with hundreds or thousands of partners or who require workflows that require more than just two parties.

Why EDI and API calls between parties aren’t cutting it

While many organizations tried to leverage electronic data interchange (EDI) and application program interface (API) to exchange documents and/or to design a set of routines, protocols, and tools for building software applications with their trading partners, the reality is these point-to-point approaches just can’t scale to meet large numbers of trading partners. They are also incapable of supporting the sophisticated, multi-party workflows that are required for most routine transactions.

A single version of the truth for your supply chain

These EDI and API “band aids” are superficial fixes for a deep problem. These methods create massive data synchronization issues because there is no single version of the truth, especially when workflows expand beyond just two parties. For instance, a simple four-party workflow is painful enough to get billing done properly as it involves participation from the hospital, a patient, attending physicians, and an insurance company. Now, imagine the complexity when you add in that patients often have to deal with multiple doctors and hospitals; doctors have to deal with multiple insurance companies; and insurance companies have to deal with multiple hospitals, doctors and patients.

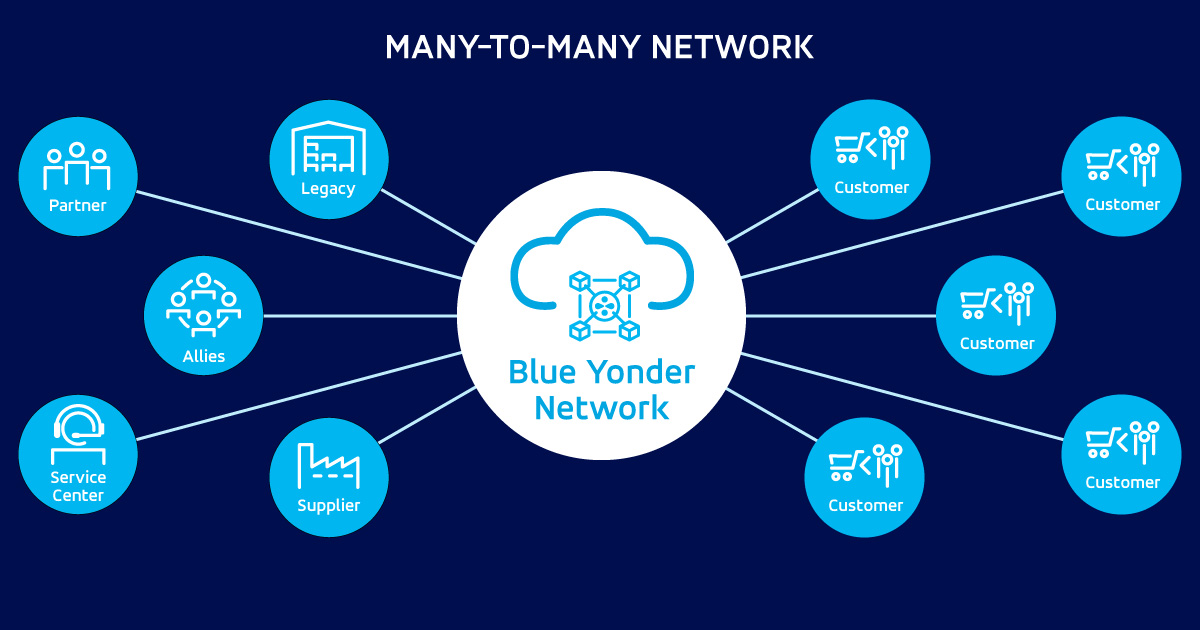

Rudimentary EDI and API techniques are simply not set up to support today’s multi-party environment never mind an organization’s digital transformation. Networks support partner connectivity and are built on a many-to-many network architecture that includes solid data governance, interoperability, enterprise system and multi-channel integration.

The components of a true supply chain network platform

A multiparty, many-to-many network connects all parties through a single connection to the network.

In the report mentioned above, Gartner advises supply chain leaders to develop a proactive strategy for engaging their business ecosystems and select the right mix of business processes and technology. But what does that mean? When it comes to selecting an effective network solution, it is critical to do your homework to ensure it includes the following capabilities:

- Multi-party transactions and master data management provide a single version of the truth. Instead of replicating data, there should be a single version of the truth mediated by a permissions model.

- Upgrade multi-party workflows while maintaining backward compatibility.

- Private processes that can be independently updated on top of shared network processes.

- Onboard once and then conduct business with anyone (subject to permissions, agreements, contracts, etc. of course).

- Near-real-time global visibility to see what’s occurring now.

- Intelligent agents that run on top of the near-real-time global backbone to provide intelligent sense-and-respond as this can dramatically increase the responsiveness, automation, and intelligence of the network. Agents can also employ machine learning to constantly improve their function.

- Tuneable system-of-control to allow individual systems or process steps to be independently moved onto the network. This is a critical capability because expecting every partner and every process to be simultaneously and fully onboarded is impossible.

- High uptimes and data access SLA’s to ensure minimal disruptions.

- A modular architecture that allows individual modules or apps to be built by different parties and then assembled into a network solution.

Why ERP and hub and spoke models fall short

Because enterprise resource planning (ERP) solutions were designed to handle private processes, they are very weak for cross-enterprise shared processes. “One-to-many networks” or the “hub-and-spoke” model where a single company (hub) surrounds itself with other companies (spokes) aren’t any better.

First, deciding which company should be the hub and which should be the spoke is hard. If you and your partners can manage to get past this, the next problem is that spokes need to onboard multiple times – once for each hub they are dealing with. This is extremely onerous and a major reason hub-and-spoke networks have failed beyond basic EDI. Aside from being unwieldy, workflows involving more than two parties become very difficult.

Networks, on the other hand, are centered around our customers attaining value. Rapid time to value means the system is self-funding versus the traditional ERP model where you bear the entire financial burden.

The Blue Yonder Network & Control Tower connects all trading partners to the AI powered network, helping you collaborate, optimize, and execute together to serve your end customers. Not only does this network help support growth and better manage capacity, it also allows all parties to concentrate on what’s most important—serving its customers. Supply chain leaders focused on manufacturing operations strategy can use this research to extend capacity planning to the full network.