The ILA Walkout Emphasizes the Need To Be Prepared for Disruptions

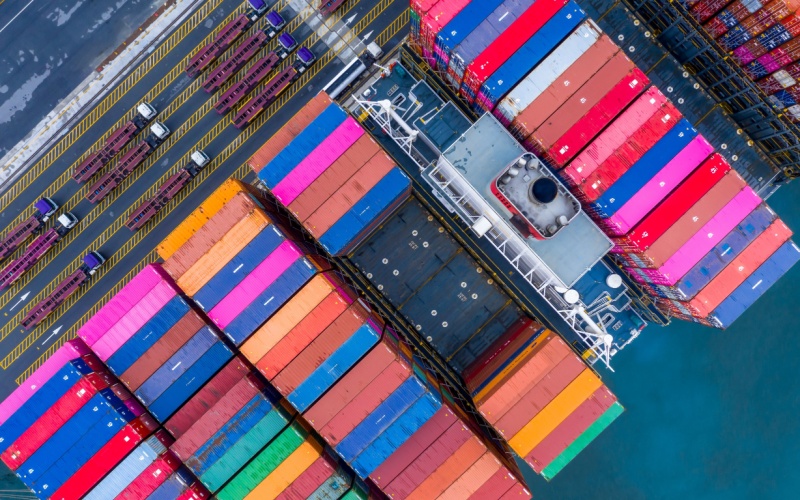

On Tuesday, the U.S. lost half of its ocean shipping capacity when the 45,000 members of the International Longshoremen’s Association (ILA) went on strike at 13 major East Coast container ports, stretching from Texas to Maine. While the walkout has been looming since June, the strike is still a surprise to many observers.

Businesses and consumers are seeing a complete stoppage of imports for many foods, beverages, cars, furniture, clothing and other products. The walkout also prevents U.S. companies from exporting products from the East Coast.

Analysts have projected that the strike will cost the U.S. economy up to $5 billion per day. And one shipping company has said that a one-week shutdown would take six weeks to recover from, as international container ships begin to back up.

There’s no doubt that this hurricane season has caused parts of the East Coast to be in great need of supplies and, unfortunately, affected infrastructure, taking out bridges and railways on needed routes for shippers. But there is some good news for both consumers and businesses. Many companies, including Blue Yonder customers, were able to identify the port shutdowns as a potential disruption in advance. By rerouting shipments, or accelerating them, they’ve been able to continue the flow of goods through their global supply chains. Experts predict that 70% of holiday-related retail goods have already reached the U.S.

But still the question remains: How can supply chain and logistics teams truly prepare for this kind of stunning disruption?

It All Begins With Real-Time, Shared Visibility

Today’s end-to-end global supply chains have become incredibly complex — spanning thousands of miles and dozens of suppliers, across multiple tiers.

Today manufacturers, retailers, distributors, and logistics services providers (LSPs) need real-time, multi-enterprise transparency with trading partners up and down the value chain. All stakeholders should be able to share the same data, as well as the same visibility into inventory, capacity, labor, fleets and other resources. Working collaboratively across their network of trading partners, companies should be able to accurately and profitably match supply and demand, seamlessly and dynamically orchestrating resources.

When a disruption like the ILA strike occurs, companies need to detect impacts at the earliest possible opportunity — and that awareness can be shared immediately across all supply chain partners and tiers. When this kind of sweeping disruption occurs, there are potentially millions of data points to consider in analyzing the situation and considering various resolutions. Historically, this kind of enormous problem could not be solved quickly or thoroughly based on manual analysis and human cognition. But today artificial intelligence (AI) makes it possible to act both rapidly and optimally.

The Blue Yonder Solution

Blue Yonder simplifies the complexity of modern supply chain and logistics operations with a single, understandable view of even the most extensive global networks. Blue Yonder’s expanded digital supply chain network capabilities are built to unify and connect these networks, no matter how large they are.

Here’s how it works: Enabled by AI, Blue Yonder’s command and control center and its AI assistants monitor conditions up and down the supply chain on a continuous basis, across as many as 150,000 trading partners. Supply chain and logistics operations can collaborate with multiple tiers within their supply chains digitally and have insights much earlier into whether and how they and their supplier and partner tiers are affected by disruptions.

When it senses an exception or anticipates an unacceptable level of risk, Blue Yonder’s command and control center and AI-powered decision engines run various scenarios that could potentially address the issue. Within minutes, the command and control center identifies the best resolution — then it instantly redirects resources, across the supply chain, to deliver the greatest impacts on service, cost, sustainability and other shared network goals. The Blue Yonder multi-tier supplier orchestration capabilities enable a supplier with limited capacity (due to the port strike or other supply chain issues) to have insights into the inventory levels of its buyers, thereby being able to balance scare resources across customers.

The Time to Act Is Yesterday

While it will never be possible to anticipate every disruption, supply chain leaders need to be prepared with solutions that meet their needs. By leveraging AI to minimize the lag time between the identification of a disruption and its successful resolution, Blue Yonder customers have a distinct advantage over competitors who are unprepared.

In the case of the ILA strike, companies using the Blue Yonder command and control center could have anticipated the event in June, when talks broke down and the risk of a walkout began to grow. They could have accelerated shipments, negotiated early with air carriers, rerouted shipments through California entry points, or pursued other resolutions. Imagine the financial and strategic difference between having this level of predictive visibility and being caught completely unaware.

The digital supply chain network, command and control center, and related multi-tier orchestration capabilities from Blue Yonder can be deployed quickly and cost-effectively to maximize your level of preparedness for the next major supply chain disruption. Contact us to learn more about how Blue Yonder can support your own emergency readiness planning.